You can read or download our latest accessories catalog below, including dead ends, jumper terminals, mid span joints, suspension clamps, repair sleeves, vibration dampers…

ECRC® conductors are installed using conventional compression fittings, to optimize costs & planning while ensuring an easy and safe installation, with minimal training for linemen.

There are several qualified hardware suppliers for ECRC®, with Sicame Group being Epsilon Cable’s preferred partner.

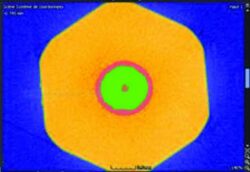

Hardware lab testing

Laboratory testing is vital in assisting both design activities and product verification. During the design stage, it supports the Technical Department in its R&D activity while in the product verification stage all Quality Control mechanical verifications and tests are carried out to include batch acceptance tests.

ECRC® accessories are tested in state of the art laboratories, which means that low sag / high ampacity conductors and accessories can be fine-tuned and qualified.

The studies and trials are performed in accordance with the power, environmental, and configuration parameters of the line to be fitted. All tests comply with the requirements of the international reference standards or/and with the technical specifications of each country.

Test performed include mechanical tests, electrical tests, combined mechanical & electrical tests, vibratory tests as well as corrosion tests (salt spray).

Learn more about type tests.

Compression fittings

Based on 20 years of experience, ECRC® accessories compression ratios have been defined to guarantee electrical continuity and ensure the mechanical resistance of the core, while optimizing the compression lengths, in order to obtain a compact, reliable and robust fitting, which is easy to install on site.