HVCRC® is a complete range of advanced conductors (also called “High Performance”, “High Capacity” or “High Temperature Low Sag” / “HTLS” conductors) made of a strong lightweight composite core and trapezoidal aluminum strands, designed to improve ampacity, reduce sag and reduce electrical losses on Transmission & Distribution lines.

Proven benefits of HVCRC® conductors:

- Improved capacity: double the line ampacity to serve increasing electrical demand, provide more flexibility for peaks in demand, reduce grid congestion and allow a smooth integration of renewables into the grid.

- Improved efficiency: reduce line losses by 30%, cutting down on generation costs and CO2 emissions, and delivering more power with the same generation capacity.

- Reduced sag & improved reliability (even at high temperature) thanks to the composite core very low coefficient of thermal expansion and high strength, making the grid more resilient and flexible.

- Fast and easy to deploy, when ampacity needs to be improved urgently to deliver more power with minimal costs and in a short timeframe.

HVCRC® conductors are ideal for reconductoring projects. They allow double the ampacity of a transmission or distribution line with minimal reinforcement of existing structures, which means optimized project costs and planning.

HVCRC® is also an interesting option for new lines as it provides an optimized long term solution in terms of flexibility, efficiency and resilience. Advanced conductors can reduce operating expenses as well as capital expenses (despite a usually higher cost for the conductor itself) as their low sag properties offer many benefits such as downsized structures (pylons & foundations) and reduced environmental impacts.

HVCRC® conductors have a proven track record with several thousands of kilometers of conductors successfully installed and energized around the world in the past decades. See case studies for examples of past projects.

HVCRC® conductors electrical conductivity is ensured by trapezoïdal strands made of highly conductive 1350-O annealed aluminum.

In some cases, Aluminum Zirconium alloy can also be used if required.

HVCRC® conductors are stranded by selected manufacturing partners around the world, which went through a strict qualification process to demonstrate their performance and quality.

Epsilon manufactures HVCRC® composite cores in pultrusion, using Aerospace grade carbon fibers and a specific matrix to ensure the highest performance and durability.

HVCRC® composite cores include a microcore and an electrically insulating external layer in glass fiber, to optimize the core performance and flexibility, and protect the aluminum strands from galvanic corrosion.

If required, CORECHECK® monitoring of the composite core allows to check its integrity before and after the conductor installation.

ASTM Qualification

HVCRC® cores are qualified according to ASTM B987-20.

ASTM B987 is the only existing standard for Carbon Composite Cores used in High Tension Low Sag Conductors. It guarantees the performance and durability of composite cores, which will withstand extreme environmental conditions during several decades of service.

Certificates available upon request.

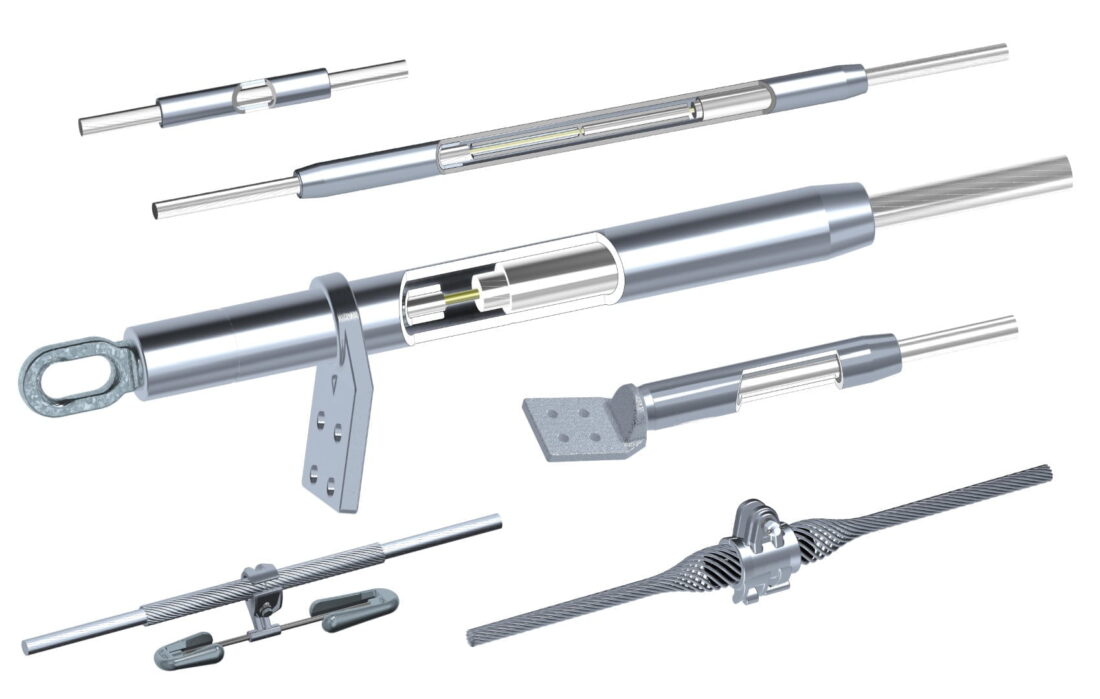

Hardware and fittings

Since 2011, Epsilon Cable and its partners developped a complete range of hardware for HVCRC® conductors, relying on the know-how and expertise of leading accessories manufacturers.

HVCRC® conductors are installed using conventional compression fittings. This reduces installation costs & complexity as compared with proprietary accessories.

This greatly reduces hardware costs, simplifies the supply chain, and guarantees utilities remain free to choose the manufacturer of their choice for their projects.

This also makes installation easier and safer, since it requires minimal training for linemen used to work with any other High Voltage conductors.

There are several approved hardware suppliers for HVCRC® worldwide, who conducted a thorough testing campaign to ensure the long term performance and compliance with requirements.

Sicame Group is Epsilon Cable’s preferred hardware manufacturer for HVCRC®. Sicame is renowned for the quality and reliability of their products, and can meet all market demands through its multiple manufacturing sites in Europe, Asia an America.

In some cases, when local content is required for the hardware, a local supplier can also be qualified.

Download our accessories catalogue

Watch our accessories e-training videos

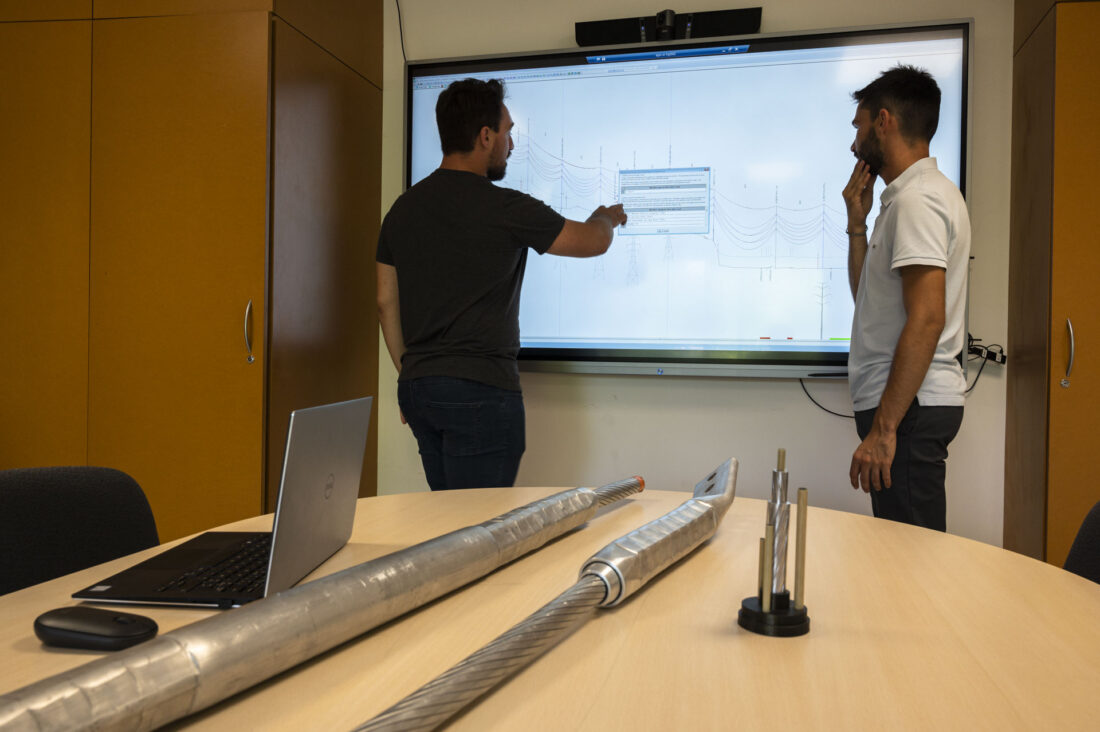

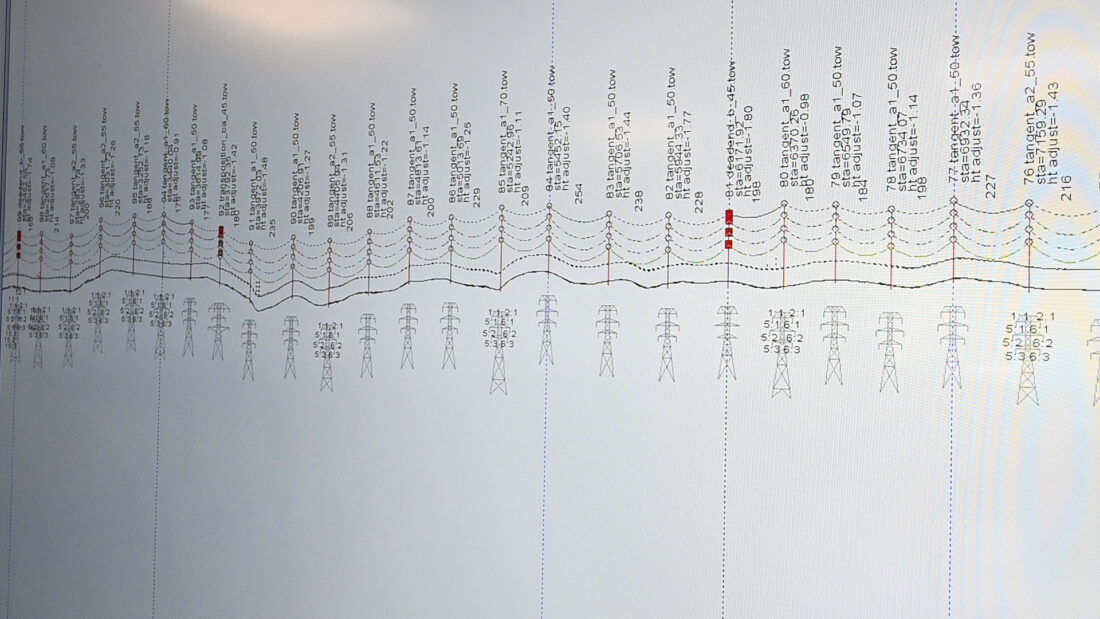

Overhead line calculation

Using the industry standard line design software (PLS CADD), Epsilon engineers can ensure our conductors will meet your performance requirements and ensure the best performance on your project: sag, maximum ampacity, conductor temperature, catenary parameter etc…

You can also download HVCRC® .WIR files for your own calculations.

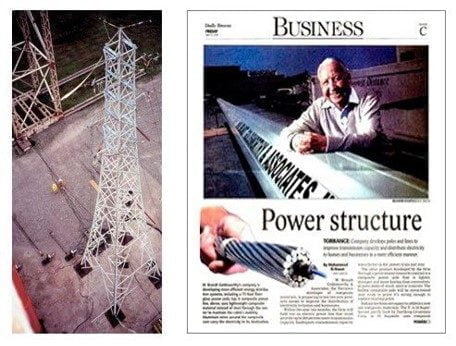

The history of HVCRC® Technology

W. Brandt Goldsworthy, nicknamed “the father of composites” and one of the inventors of the pultrusion process, could see as early as the 90’s the potential for improving overhead lines thanks to pultrusion.

He had the idea to replace the traditional steel core in High Voltage cables with a composite core, and in 1998, his team laid out the foundation for the first generation of composite cables.

Epsilon’s founder Stéphane LULL and his associate Laurent GUITTON (VP) had the opportunity to work with M. Goldsworthy in California around the same period, before he passed away. We are proud to have carried on his work and his legacy to this date, as we refined the pultrusion process and developed the HVCRC® with partners from all over the world.

The HVCRC® technology is now widely used by transmission and distributions utilities looking for a reliable and durable solution to upgrade overhead lines.

Frequently Asked Questions

We answered below some of the most common questions we get about HVCRC®:

How can I predict the lifetime of my line if I install composite core conductors?

Our composite experts have developed a powerful simulation tool for the ageing of our composite core in real life conditions. Based on this unique model, we are able to assess the lifetime of the conductors based on the real use of the line and the end of life criterion set by the utility.

The presentation of this model won the Next Generation Network Award at CIGRE 2022 in Paris (read more).

How can I check the composite core?

Our CORECHECK® technology allows to check the structural integrity of our composite cores at any stage of their life: after the pultrusion process, after stranding, after transport, after installation, and at any time in the conductor lifetime.

Is HVCRC® suitable for ice-loads? How much ice can it bear?

HVCRC® can safely be used in areas with ice-loads requirements, such as cold continental climates or mountain areas. Depending on the ice-load requirements, we recommend to use HVCRC® ULS, which uses a composite core made out of an even higher grade of carbon fiber (see mechanical properties)

Depending on your project, a 100% carbon fiber core solution with aluminium tubing can also be an excellent choice when ice loads are a major factor. Epsilon is also manufacturing such cores for stranders who developed their own HTLS solution, such as Nexans and De Angeli Prodotti.

Please contact our experts for a custom study about the acceptable ice load for your projects.

Can I use “collet” fittings with HVCRC® conductors?

We do not recommend it, even though it is possible from a technical perspective.

Collet fittings are a costly and proprietary solution from 1 company, which introduce unnecessary costs, delays and complexity as compared with compression fittings.

Epsilon and its partners developed specific fittings based on standard compression techniques, which are manufactured by qualified hardware manufacturers to ensure their reliability. For every HVCRC® project, compression fittings save a lot of time and money to contractors and utilities, without any failure.

Are HVCRC® conductors compliant with ASTM B987 standard?

Yes, HVCRC® is qualified according to ASTM B987-20. Our certificates are available upon request.

An Epsilon expert is also part of the ASTM B987 panel, to ensure the continuous update and improvement of the standard.

What is the highest temperature HVCRC® conductors can withstand?

As per ASTM B987 standard, our HVCRC® composite cores are designed and qualified to withstand 180°C in continuous operations, and up to 200°C (392°F) in emergency situation.

For higher requirements, please contact our experts for a specific study.

Has there been any known failure of HVCRC® conductors?

No. Among the main composite core solutions on the market, HVCRC® is the only one without any known failure.

We believe this track record is the result of various factors, starting with our unique experience and know-how in carbon fiber pultrusion for demanding applications (industry, aerospace & energy), as well as the extreme care we put into the design, manufacturing and installation of the conductors.

More generally, to this day there has never been a failure on a project equipped with Epsilon cores (including our 100% carbon fiber rods).

When was the first HVCRC® conductor installed?

The first HVCRC® conductor was installed in 2012 in Kazakhstan for utility Alatau Zharyk, closely followed by a project in Mexico for CFE (Comisión Federal de Electricida) and a pilot project in Korea for Kepco.

10 years later, thousands of kilometers of HVCRC® conductors have successfully been installed on every continent.