All our composite cores are manufactured using the Pultrusion process in our French facilities.

Conductor stranding is then performed by our manufacturing partners worldwide, as close as possible to the end market.

Pultrusion

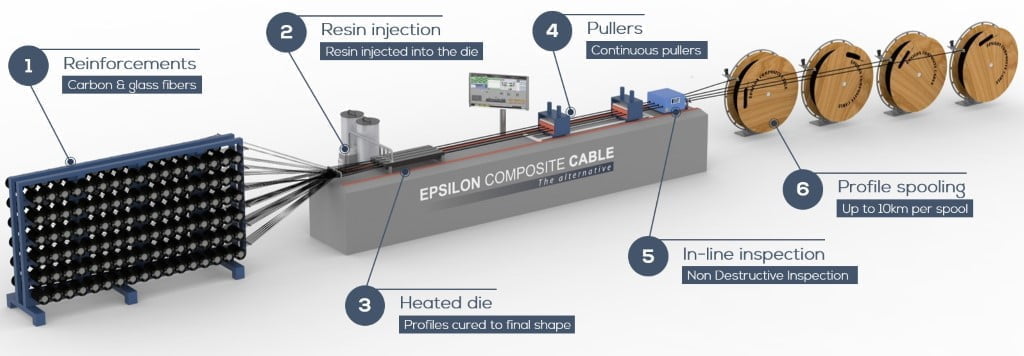

Pultrusion is an automated process that allows the continuous production (24/7 production) of high performance composite profiles, such as rods or flat laminates.

Pultrusion of carbon fiber is the historical core business of Epsilon Composite, the world leader of this industry since 1987.

The term “pultrusion” is the contraction of “pull” and “extrusion”. Extrusion is a continuous manufacturing process for plastic or metal profiles in which the material is pushed through a die of a specific shape. In pultrusion, the material is simply pulled through a heating die instead of being pushed.

Pultruded are cut to the desired length at the end of the production line, so profiles can be spooled at the desired length around a drum (up to 10km).

Control laboratory – product testing

In addition to a tight control of process parameters and incoming raw materials, Epsilon has more than 30 years of experience of physico-chemical testing (Tg / DMA, DSC, microscopic observations, etc.) and mechanical testing (tensile/compression tests, bending, fatigue, ILSS, etc.) on composite materials and metals.

Our laboratory is also an essential component of our R&D effort, since it allows us to test the performance of the materials we develop, as well as to verify the consistency of our predictive simulations through real tests. These tests can simulate ageing or environmental aggressions (UV, high temperature, humidity, contaminating fluids, etc.)

Epsilon has also developed a proven expertise in non-destructive testing, based on a complete panel of technologies that make it possible to detect any defects in the composite parts we produce (delamination, porosity, foreign body…).

Stranding

Stranding of HVCRC® conductors is performed by our stranding partners. Most of those partners have a long history of manufacturing HTLS conductors, including HVCRC® or alternative HTLS solutions. Having experienced stranders around the world with proven capabilities is a key point to manufacture HVCRC® conductors and contribute to improve the performance, efficiency and reliability of overhead power lines.

Epsilon is historically known for its collaborative approach with all its partners, favouring long-term and mutually beneficial relationships based on respect, trust and continuous improvement.

Our composite and stranding experts are also able to support new stranding partners who want to diversify their product portfolio with HVCRC®. In that case, we can propose a custom industrial support, initiate a track record with a pilot line, and progressively move on to larger projects on both domestic markets and export markets.

Interested in becoming an approved HVCRC strander ? Contact us to discuss your project.