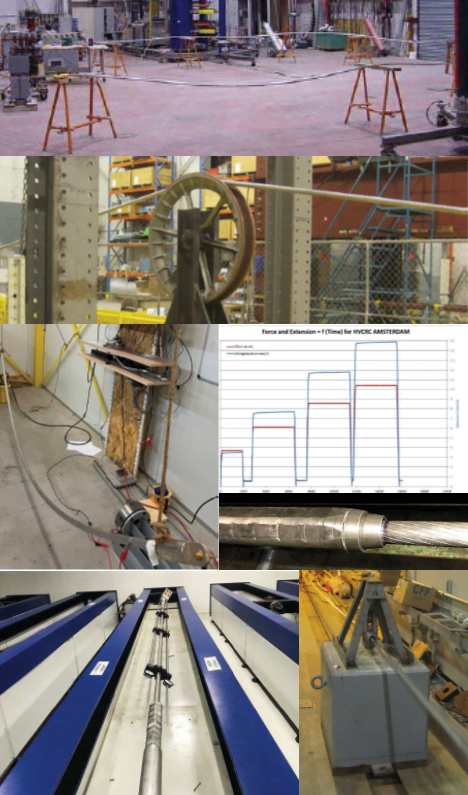

Different type tests performed on different sizes:

Type tests on composite cores

ASTM B987 certification on different diameters and grades of HVCRC® core.

- High Strength grade

- Extra High strength grade (ULS)

Type tests on conductors

- Stress-strain

- DC resistance

- Ultimate tensile strength

- Temperature cycle test

- Creep test

- Sheaves test

- Torsional ductility test

- Aeolian vibration

- High temperature creep

Type tests on accessories

- Tensile test on dead end

- Tensile test 168h

- Heat cycle test

Reports available on request